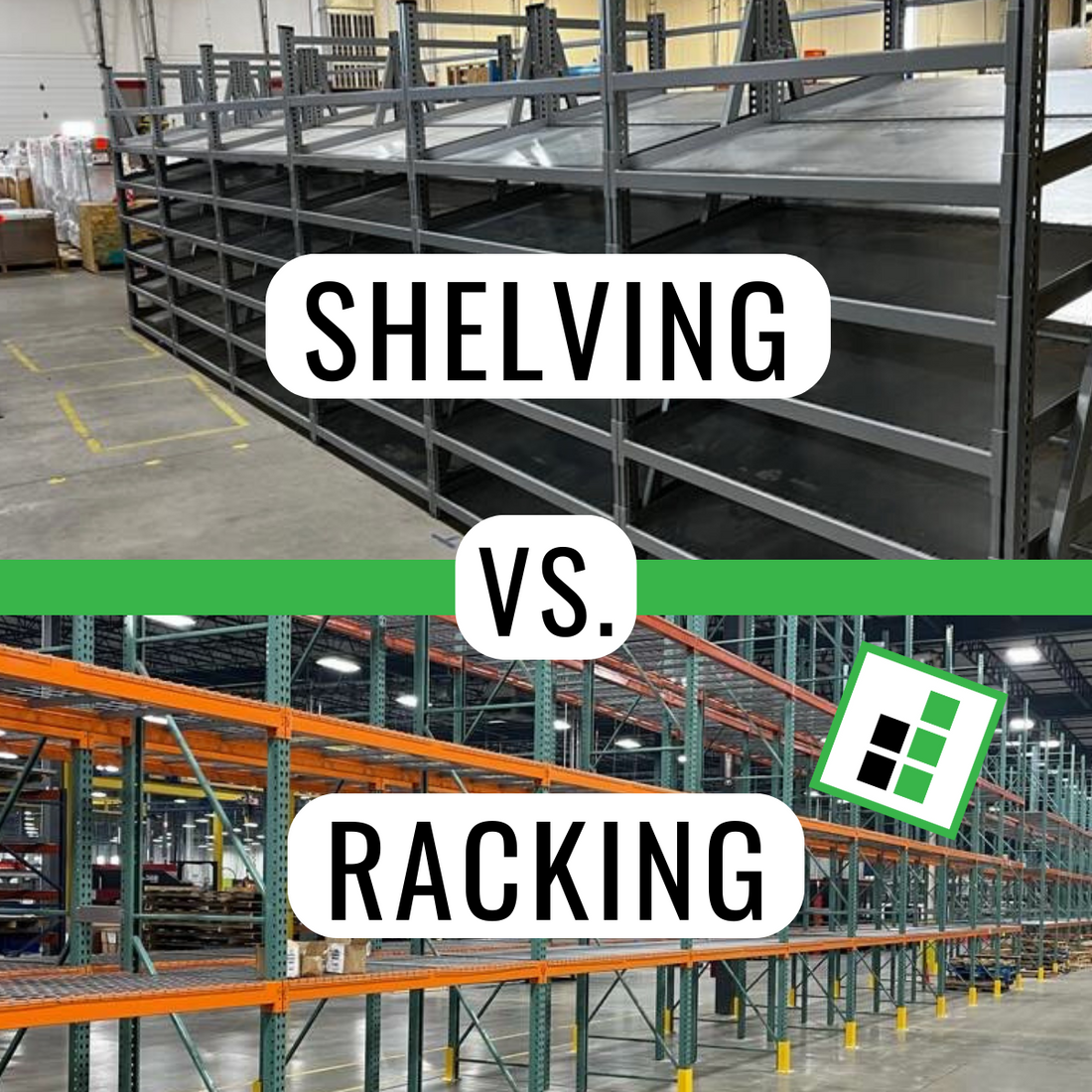

Shelving vs. Racking - Aren't they the same thing?

Share

As Solution Engineers, we get this question a lot - And although they are both means of storage in the warehouse, they certainly have their differences! Read on to learn what type works better in specific settings.

Racking and shelving are often used interchangeably, but they are two different storage solutions based on size, weight capacity and style. Racking is a system of vertical frame uprights and horizontal step beams that primarily support pallets of goods on wire decks or pallet supports. It is a more heavy-duty storage option, rated to higher capacities based a beam face height and desired decking. They’re typically used in warehouses, cold storage facilities and distribution centers where larger, bulk quantities of goods need to be stored. Single deep, selective rack is the most common, however there are higher dense systems that accommodate multiple pallets deep (Drive-in, pushback and pallet flow).

On the other hand, shelving is a system of horizontal shelves that are supported by vertical posts. It’s a better solution for storing smaller, higher moving, easily accessed items in a manufacturing facility, production line, retail stores or smaller storage rooms. The shelf levels are lighter in terms of capacity, using solid metal, particle board or wire for decking. Like pallet racking, widths and depths are customizable but on a much smaller scale - Unlike the bulkier industrial stuff, shelving allows features like modular drawers, perforated end panels, solid backs, bins and more. Other styles include high bay, sloped and carton flow shelving systems.

In certain applications, racking and shelving can be used together. For example, a warehouse may use racking to store larger, palletized items above shelving placed in the bottom of the bay - This combination of storage solutions allows for efficient use of space and easy organization of goods. Reach out to one of our solutions engineers with questions or to get assistance on laying out your space with either storage type.