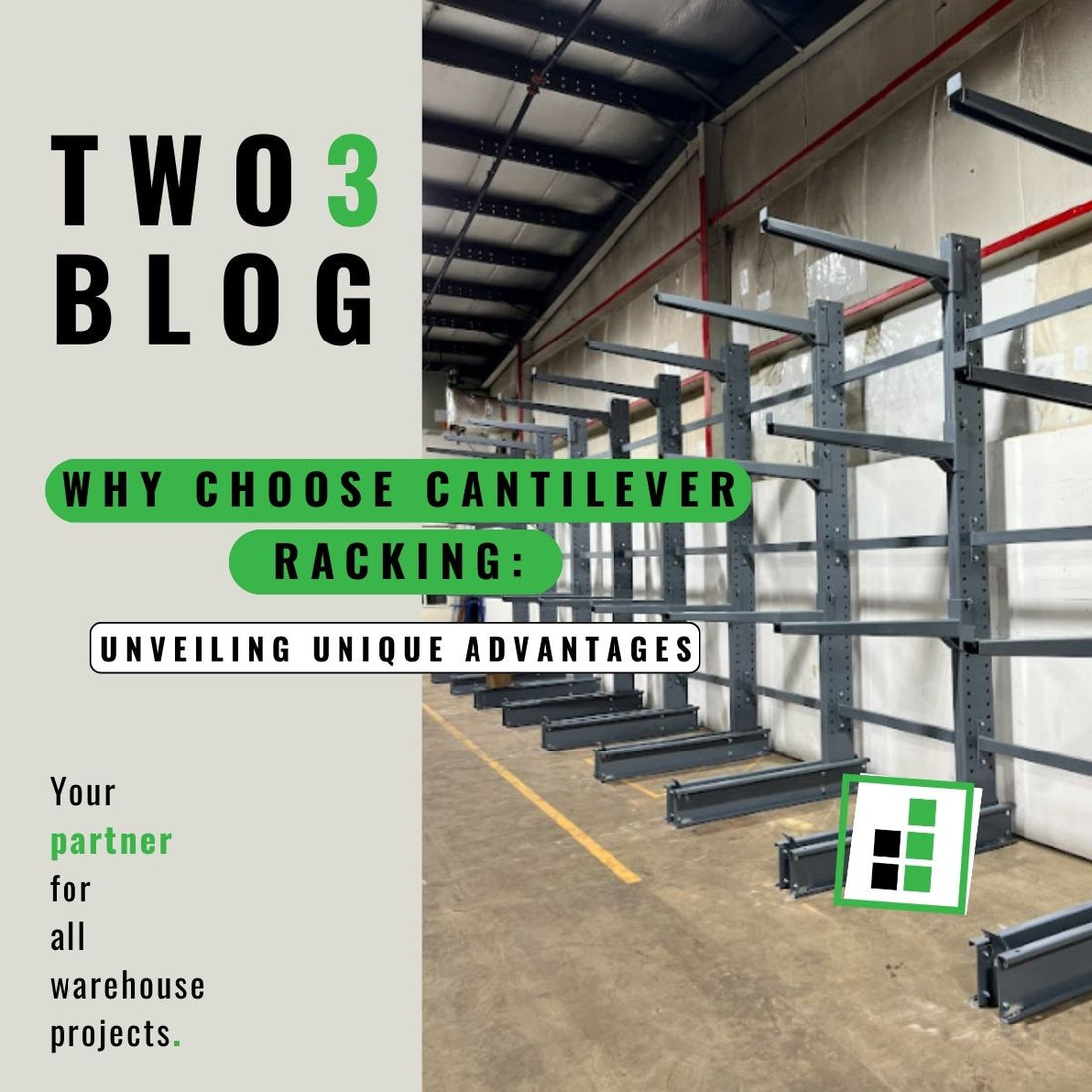

Why Choose Cantilever Racking: Unveiling Unique Advantages

Share

Is Cantilever Racking the Ultimate Solution for Your Warehouse Storage Needs?

In the world of warehouse racking systems, each type offers specific benefits tailored to various storage needs. Among these, cantilever racking stands out for its unique design and versatility, particularly suited for storing long, bulky, or irregularly shaped items. This blog post explores the advantages of cantilever racking and why it might be the superior choice for certain warehouse operations over other racking solutions.

Accommodating Diverse and Bulky Items

The primary benefit of cantilever racking is its ability to store items that would not fit comfortably or safely on traditional pallet racks. This includes long materials like lumber, pipes, and carpets, as well as bulky items like furniture or large machinery parts. The absence of front columns in the design of cantilever racks allows for easier loading and unloading of such items. This open-front design not only accommodates a wide range of item sizes and shapes but also reduces the risk of damage during handling, a common issue with more restrictive racking systems.

Enhanced Accessibility and Space Utilization

Cantilever racking systems offer unparalleled accessibility. With no vertical obstructions at the front of the racks, forklifts and other loading machinery can easily approach and maneuver around the racks. This ease of access not only speeds up the handling process but also reduces labor effort and time. Additionally, cantilever racks can be built to various heights and lengths, maximizing vertical and horizontal space in a warehouse. This adaptability in design allows for more efficient use of space, a crucial factor in warehouse management.

Customization and Scalability

Another significant advantage of cantilever racking is its high degree of customization and scalability. The arms, bases, and braces of these racks can be adjusted and reconfigured to accommodate changes in the type or size of items being stored. This flexibility ensures that the racking system can evolve alongside the changing needs of a business, making it a long-term storage solution. Whether a warehouse's inventory profile shifts or expands, cantilever racking can adapt without the need for a complete overhaul.

Conclusion

Cantilever racking is an excellent solution for warehouses that handle long, bulky, or irregularly shaped items. Its open-front design, enhanced accessibility, and customizable nature make it a standout choice compared to more traditional racking systems. By choosing cantilever racking, warehouses can not only improve their storage efficiency and space utilization but also enjoy a flexible system that can grow and change with their business needs. For many warehouse operations, the benefits of cantilever racking offer a clear path to improved productivity and operational efficiency.

FAQs

- What types of items are best suited for cantilever racking?

Answer: Cantilever racking is ideal for storing long, bulky, or irregularly shaped items such as lumber, pipes, carpets, furniture, and large machinery parts. - How does cantilever racking compare to traditional pallet racks?

Answer: Cantilever racking differs from traditional pallet racks by featuring an open-front design that allows for easier loading and unloading of long or bulky items without front columns obstructing access. - What are the advantages of the open-front design in cantilever racking?

Answer: The open-front design of cantilever racking accommodates a wide range of item sizes and shapes, reduces the risk of damage during handling, and enhances accessibility for forklifts and other loading machinery. - Can cantilever racking be customized to fit specific warehouse needs?Answer: Yes, cantilever racking systems offer a high degree of customization, allowing for adjustments and reconfigurations of arms, bases, and braces to accommodate changes in inventory or storage requirements.

- What safety considerations should be kept in mind when using cantilever racking?

Answer: Safety measures such as load capacity limits, proper load distribution, regular inspections for damage or wear, and employee training on safe handling procedures are essential when using cantilever racking systems.