We look forward to connecting with you!

Pallet Racking

Optimize your warehouse storage with customizable industrial pallet racking systems designed for maximum efficiency and flexibility. With multiple styles—Selective, Double-Deep, Push Back, and more—pallet racking accommodates various product sizes, load weights, and retrieval methods, whether you're using forklifts, order pickers, or manual handling. Tailored to your clear height, aisle layout, load capacity, pallet type, and safety needs, these systems can be optimized for speed of access, high-density storage, or multi-SKU operations. Safety features like upright guards, row spacers, beam locks, and seismic bracing ensure reliability and protection, while your choice of colors, finishes, and beam configurations reflect your operational and aesthetic requirements.

Shelving

A flexible storage system ideal for smaller, non-palletized items in warehouses, distribution centers, and retail or stockroom environments. Constructed with metal frames and multiple adjustable shelves, shelving systems enhance organization, streamline manual order-picking, and make efficient use of vertical space. Available in boltless, wire, and industrial steel styles, these units can be standalone, back-to-back, or part of a multi-level setup. Features—from drawers and dividers to pegboards and bins—are customizable, as are shelf materials (solid, plywood, wire mesh, perforated), heights up to around 10′, and color options. Aisles can be optimized for foot traffic, rolling ladders, or carts, making shelving a highly adaptable, cost-effective solution for manual inventory handling.

Carton Flow

Carton flow racking is a gravity-driven storage system that keeps operations moving smoothly. Utilizing gently inclined roller tracks or wheeled lanes, cartons, totes, or bins automatically advance to the pick face as each item is removed—enabling true first-in, first-out (FIFO) inventory rotation. This setup is especially well-suited for fast‑paced order fulfillment centers, distribution hubs, and assembly lines.

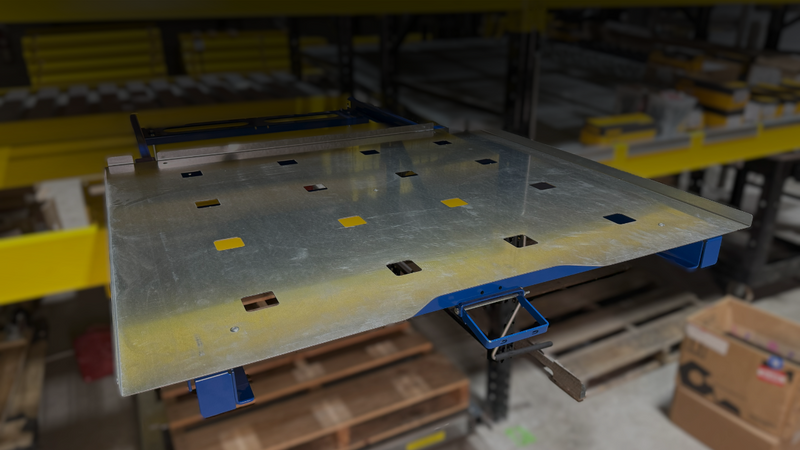

Mezzanines & Platforms

Maximize your warehouse’s vertical capacity by installing an elevated steel structure—mezzanine or platform—to create additional floor space for storage, offices, or production without costly building expansion. Custom‑engineered to your layout, these structures can be freestanding, rack‑supported, or integrated into existing building infrastructure. Designed to streamline workflow and separate functions (like packing, assembly, or inventory staging), mezzanines also bring safety and flexibility with modular decks, stairs, handrails, pallet gates, and custom color options. Tailored choices in decking (ResinDek, diamond‑plate, bar grating), clear height, support columns, kickplates, and more ensure a solution that fits your operational needs and grows with your business.

Cantilever Racking

Store long, bulky, or irregular items—lumber, pipe, steel, furniture—without upright interference. Cantilever systems use vertical columns with adjustable arms that create an open-front design for fast loading, clean picks, and less product damage. Available single- or double-sided and built heavy-duty for indoor or outdoor use, each layout is tailored to your product dimensions, capacities, clear height, forklift reach, and aisle spacing.

Drive-in racking

Maximize storage density by eliminating excess aisles with a drive-in system designed for bulk, uniform pallet loads. Forklifts drive directly into the rack structure, placing pallets on continuous rails for Last-In, First-Out (LIFO) inventory management. Ideal for storing large quantities of the same SKU, drive-in racking is commonly used in cold storage, food distribution, and other high-volume environments where space is at a premium. Each system is engineered to your pallet size, load capacity, forklift type, and clear height, ensuring a safe, efficient, and space-optimized layout.

Push-Back Racking

Achieve high-density, efficient pallet storage with a semi-automated push-back system that maximizes warehouse space and speeds up handling. This Last-In, First-Out (LIFO) solution stacks pallets up to six deep on nested carts riding on inclined rails—each loaded pallet pushes the previous ones back, and when you retrieve a pallet, the remaining ones roll forward for easy access. Minimizing aisle requirements, it reduces forklift travel, cuts down on product handling damage, and is ideal for high-turnover inventory situations. Fully customizable—including custom frame colors and adaptation to pallet type—each system is engineered to your product dimensions, clear height, forklift reach, and building layout.

Tenant Lockers

Wire mesh tenant lockers offer secure, ventilated storage solutions ideal for shared environments like apartments, gyms, and warehouse breakrooms. These customizable modular units provide open-grid visibility and airflow, helping to prevent moisture buildup and odors—perfect for storing uniforms, sports gear, or seasonal items. Available in single‑tier and multi‑tier configurations, they come with lockable doors (padlock or built‑in options) and can be tailored in size, mesh style, ceiling panels, and locking mechanism to fit your space and security needs.