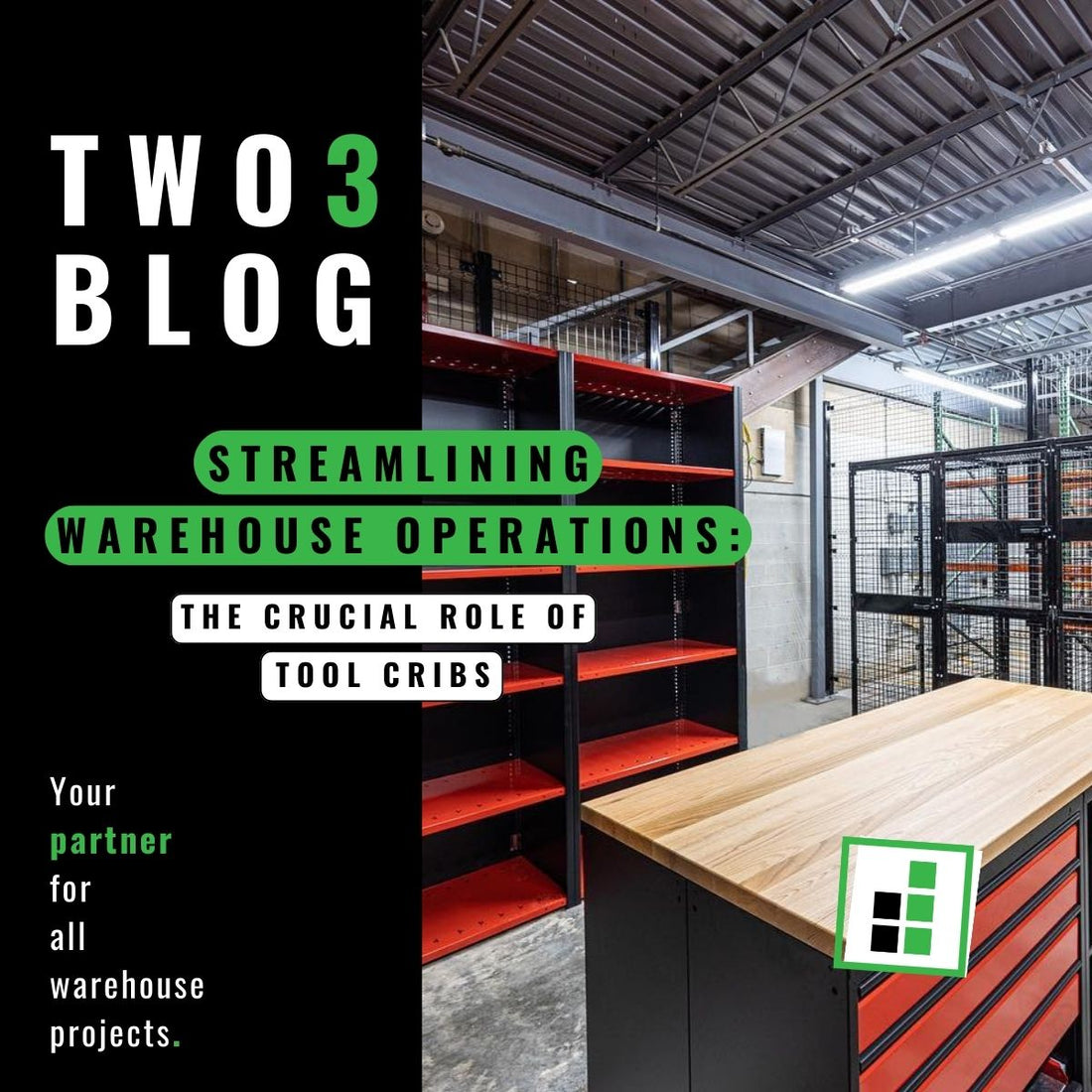

Streamlining Warehouse Operations: The Crucial Role of Tool Cribs

Share

Is Your Warehouse Missing Out on Efficiency? The Power of Tool Cribs Unveiled!

In the fast-paced world of warehousing, efficiency and organization are the keys to success. Warehouse managers continually seek ways to streamline processes, reduce downtime, and optimize resources. One often-overlooked yet critical element in achieving these goals is the tool crib. In this blog post, we will delve into the essential role that tool cribs play in warehouse operations and how they contribute to enhancing productivity, accountability, and overall efficiency.

What is a Tool Crib?

A tool crib is a designated, secure area within a warehouse or manufacturing facility where tools, equipment, and supplies are stored, organized, and managed. This controlled environment serves as the nerve center for tools and ensures they are readily available for workers while maintaining strict accountability.

The Role of Tool Cribs in Warehouse Operations

Enhanced Organization

The foremost role of a tool crib is to provide a structured and organized storage space for tools and equipment. In a typical warehouse, tools can be scattered throughout various locations, leading to chaos, inefficiency, and time wasted searching for the right tool. A tool crib centralizes all tools, making them easily accessible and well-organized. This reduces the risk of tools being lost or misplaced, and it simplifies the tool retrieval process.

Accountability and Control

Accountability is a fundamental aspect of tool cribs. When tools are checked in and out of the crib, there is a clear record of who used each tool and when. This accountability discourages misuse, loss, or theft of tools. Knowing who is responsible for tools helps maintain them in good working condition, as users are more likely to report issues promptly.

Minimized Downtime

Downtime in a warehouse can be a costly affair. Every minute spent searching for tools or equipment is a minute that could be used for productive work. Tool cribs significantly reduce downtime by ensuring tools are readily available and easy to locate. This efficiency boost translates into increased productivity and cost savings.

Improved Safety

Safety is a top priority in warehouse operations. Tool cribs contribute to a safer work environment by keeping tools organized and out of high-traffic areas. This minimizes the risk of accidents caused by tripping over tools or equipment left in the workspace. Additionally, well-maintained tools in the crib reduce the likelihood of accidents due to malfunctioning equipment.

Inventory Management

Effective inventory management is crucial for controlling costs and optimizing operations. Tool cribs provide precise control over tool inventory. Warehouse managers can track the quantity and condition of each tool, ensuring that replacements or repairs are made when necessary. This level of control helps prevent unnecessary expenses and ensures that the right tools are always available when needed.

Theft Prevention

Warehouses can be tempting targets for theft, especially when valuable tools and equipment are involved. Tool cribs act as a deterrent to theft by providing a secure and controlled environment for valuable assets. Unauthorized access is restricted, reducing the risk of theft and loss.

Conclusion

Tool cribs are indispensable assets in the world of warehousing and manufacturing. They play a pivotal role in enhancing organization, accountability, and efficiency while contributing to improved safety and inventory management. By implementing a well-designed tool crib in your warehouse operations, you can unlock the potential for increased productivity, reduced downtime, and cost savings. It's a strategic investment that leads to a more streamlined and successful warehouse operation.

FAQs:

- What is a tool crib, and how does it work?

Answer: A tool crib is a designated, secure storage area in a warehouse or facility where tools, equipment, and supplies are stored, organized, and managed. It works by centralizing tools, ensuring they are readily available while maintaining strict accountability through check-in and check-out procedures. - How does a tool crib enhance organization in a warehouse?

Answer: Tool cribs enhance organization by providing a structured storage space for tools, reducing the risk of tools being lost or misplaced. They centralize tools, making them easily accessible and well-organized, streamlining the tool retrieval process. - What role does accountability play in tool crib management

Answer: Accountability is crucial in tool crib management. When tools are checked in and out of the crib, there is a clear record of who used each tool and when. This discourages misuse, loss, or theft of tools and ensures prompt reporting of any issues, contributing to better tool maintenance. - How can tool cribs help minimize downtime in warehouse operations

Answer: Tool cribs minimize downtime by ensuring tools are readily available and easy to locate. This efficiency boost translates into increased productivity, as workers spend less time searching for tools or equipment, thus reducing costly downtime. - What are the security benefits of using a tool crib?

Answer: Tool cribs provide security benefits by offering a secure and controlled environment for valuable tools and equipment. Unauthorized access is restricted, acting as a deterrent to theft and loss. This added security helps protect valuable assets within the warehouse.